OMP400 compact high accuracy touch probe

OMP400

|

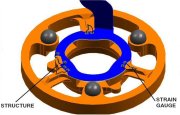

The OMP400 is an ultra compact probe, ideally suited to small to medium machining centres. It combines the miniaturisation of the highly successful OMP40 probe with new advances in strain gauge technology, pioneered by Renishaw's high accuracy MP700 probe. Strain gauges attached to the structure measure the smallest of stylus motions, allowing for a very sensitive system. The innovative RENGAGE™ technology built into the OMP400 brings unrivalled performance in terms of 3D measurement. Use OMP400 with Renishaw OMV for advanced on-machine verification when machining contoured surfaces and complex shapes. |

OMP400 features and benefits

|

|

OMP400 system options

|

OMP400 with OMI-2T |

OMP400 with OMI-2 |

OMP400 with OMI |

OMP400 with OMM / MI 12 | |||

|---|---|---|---|---|---|---|

|

|

|  |

|||

| Offers a state-of-the-art modulated optical transmission method and the twin probe option. | Offers a state-of-the-art modulated optical transmission method. | Ideal for factory fitment by machine tool builders. | Offers installation flexibility making it ideally suited for retro-fitting in the field. |

![]()

OMP400 Specification

| Specification | |

|---|---|

| Principal application | Small to medium machining centres and mould & die applications |

| Weight (without shank in g) with batteries without batteries |

262 g (9.24 oz) 242 g (8.53 oz) |

| Sense directions | Omni-directional: ± X, ± Y, +Z |

| Uni-directional repeatability | 0.25 µm (10 µin) 2 sigma 50 mm stylus

length* 0.35 µm (14 µin) 2 sigma 100 mm stylus length |

| 2D lobing in X, Y | ± 0.25 µm (10 µin) 2 sigma 50 mm

stylus length* ± 0.25 µm (10 µin) 2 sigma 100 mm stylus length |

| 3D Lobing in X, Y, Z | ± 1.00 µm (40 µin) 2 sigma 50 mm

stylus length* ± 1.75 µm (70 µin) 2 sigma 100 mm stylus length |

| Trigger speed range | 10 mm/min to 1 m/min |

| Stylus trigger force** XY plane + Z direction |

0.06 N, 6 gf (0.22 ozf) typical minimum 2.55 N, 260 gf (9.17 ozf) typical minimum |

| Stylus overtravel force** XY plane +Z direction |

1.04 N, 106 gf (3.74 ozf) typical

minimum§ 5.5 N, 561 gf (19.78 ozf) typical minimum † |

| Stylus overtravel XY plane +Z direction |

± 11° 6 mm (0.23 in) |

| Battery life - stand-by - 5% usage - continuous life |

Legacy / Modulated mode One year 90 / 110 days 110 / 105 hours |

| Sealing | IP X8 (BS 5490, IEC 529) 1 atmosphere |

| Shanks | Various |

| Compatible interface | Legacy mode: OMI or OMM / MI 12 |

* Performance specification is for a test velocity of 240 mm/min (9.45 in/min) with a 50 mm carbon fibre stylus. Test velocity does not constrain performance in application.

** The stylus trigger force is the force exerted on the

component when the probe triggers. However, the maximum

force applied to the component will occur after the trigger

point and will be greater than the trigger force. The

magnitude depends on a number of factors affecting probe

overtravel including

measuring speed and machine deceleration. If the forces

applied to the component are critical, contact Renishaw for

further information.

§ Stylus overtravel force in XY plane occurs 70 µm after the trigger point and rises by 0.1 N/mm, 10 gf/mm (9.1 oz/in) until the machine tool stops (in the high force direction and using a 50 mm carbon fibre stylus).

† Stylus overtravel force in + Z direction occurs 10 to 11 µm after the trigger point and rises by 1.2 N/mm, 122 gf/mm (109.6 oz/in) until the machine tool stops.

![]()

OMP40-2 software options

EasyProbe - entry-level package for simple work piece set-up

Inspection - basic set-up and work piece inspection cycles, with automatic update of offsets

Inspection Plus - an integrated suite of inspection cycles including vector measurement

Productivity+ Active Editor Pro - a PC-based software package with GUI, allowing the user to select features directly from an imported CAD model, making the generation of probing cycles even easier.

Renishaw OMV - A PC-based software package for verification of complex parts and live data capture to PC during probing for instant feedback on component quality.

![]()

Download

Data Sheet

-

[410kB]

OMP400 data sheet

[410kB]

OMP400 data sheet

-

[85kB]

Taper shanks for machine tool probes data sheet

[85kB]

Taper shanks for machine tool probes data sheet

-

[43kB]

Shank modifications for machine tool probes data sheet

[43kB]

Shank modifications for machine tool probes data sheet

Learn more

Marketing literature

-

[80kB]

OMP400 flyer

[80kB]

OMP400 flyer