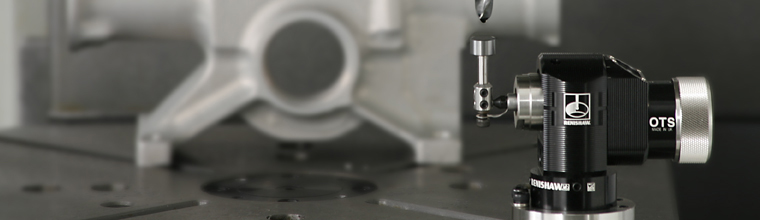

OTS contact laser tool setter

OTS

|

|

OTS features and benefits

|

|

| Sense directions | ±X, ±Y, +Z |

|---|---|

| Weight 1/2 AA AA |

450 g (16 oz) 490 g (18 oz) |

| Transmission type | Infra-red optical transmission |

| Uni-directional repeatability (max 2 sigma at stylus tip) |

1.0 µm (0.00004 in) |

| Trigger force Lowest force Highest force |

1.3 N (4.6 ozf) 2.4 N (8.5 ozf) |

| Stylus overtravel XY plane +Z direction |

±3.5 mm (0.14 in) 6 mm (0.23 in) |

| Sealing | IP X8 |

| Mounting | 12.7/10 mm (0.5/0.39 in) caphead bolt (not supplied). Optional spiral pins to allow accurate re-mounting. |

| Compatible interface | OMI-2T/OMI-2 |

Software for OTS

Renishaw tool setting software allows you to set tool length and diameter offsets for single point and multiple point tools, perform in cycle broken tool detection and manual or automatic updates.

![]()

Download

Data sheet

-

[299kB]

OTS Data sheet

[299kB]

OTS Data sheet

Marketing literature

-

[168kB]

Twin probe system flyer

[168kB]

Twin probe system flyer

Installation guide

-

[865kB]

OTS Installation guide

[865kB]

OTS Installation guide

Quick start guide

-

[2.5MB]

OTS Quick start guide

[2.5MB]

OTS Quick start guide

The

OTS uses the

The

OTS uses the