RMP600 high accuracy touch probe

RMP600

![]() ชม วีดิโอคลิปสาธิตทำงาน

ชม วีดิโอคลิปสาธิตทำงาน

|

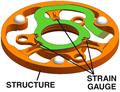

The Renishaw RMP600 is a compact, high accuracy touch probe with radio signal transmission, offering all the benefits of automated job set-up, plus the ability to measure complex 3D part geometries on all sizes of machining centres including 5-axis machines. The RMP600 successfully combines the patented RENGAGE™ strain gauge technology with the unique frequency hopping radio transmission system from the RMP60. Strain gauges attached to the structure measure the smallest of stylus motions, allowing for a very sensitive system. This innovative RENGAGE™ technology built into the RMP600 brings unrivalled performance in terms of 3D measurement. Use the RMP600 with Renishaw OMV for advanced on-machine verification when machining contoured surfaces and complex shapes. The 2.4 GHz frequency band is compliant with radio regulations in the EU, USA, Japan, Canada, Switzerland, Australia, New Zealand, Taiwan, India, Indonesia, South Korea, Malaysia, Singapore and China. |

- Patented RENGAGE™ technology gives very low and highly consistent contact forces as well as Sub micron 3D performance on contoured surfaces

- Increased stylus lengths can be supported without a significant decrease in probe performance

- Frequency hopping spread spectrum (FHSS) transmission means that once partnered, the RMP600 and RMI hop frequencies together to provide reliable communications

- The RMP600 utilizes accelerometers to detect shock and motion to assess whether stylus forces are due to valid triggers or high speed acceleration

- Multiple probe mode is available on RMP600 to allow the use of many different probes with the same RMI receiver

- 3D performance is ideal for the calibration and mapping of 5-axis machines

![]()

RMP600 software options

EasyProbe - entry-level package for simple work piece set-up

Inspection - basic set-up and work piece inspection cycles, with automatic update of offsets

Inspection Plus - an integrated suite of inspection cycles including vector measurement

Productivity+™ Active Editor Pro - a PC-based software package with GUI, allowing the user to select features directly from an imported CAD model, making the generation of probing cycles even easier.

![]()

Download

Data sheets

-

[624kB]

RMP600 data sheet

[624kB]

RMP600 data sheet

-

[85kB]

Taper shanks for machine tool probes data

sheet

[85kB]

Taper shanks for machine tool probes data

sheet

-

[43kB]

Shank modifications for machine tool probes

data sheet

[43kB]

Shank modifications for machine tool probes

data sheet

Learn more

Marketing literature

-

[701kB]

RMP600 flyer

[701kB]

RMP600 flyer

Quick start guide

-

[13.9MB]

RMP600 Quick start guide

[13.9MB]

RMP600 Quick start guide