SPRINT™ : Blade Toolkit

SPRINT on-machine scanning system for high-speed blade measurement

![]() ชม วีดิโอคลิปสาธิตทำงาน

ชม วีดิโอคลิปสาธิตทำงาน

The SPRINT Blade Toolkit offers a unique solution to end users requiring measurement data for the production and repair of blades and bladed disks. The data can be used in a number of high-precision applications including blade tip refurbishment, in-process blade measurement and root blending of bladed disks.

In comparison with traditional on-machine technologies, the SPRINT Blade Toolkit provides significant cycle time advantages, and uniquely accurate definition of tightly curved surfaces such as leading edges. It also provides significant advantages in adaptive machining processes when compared to off-machine measurement methods, since measuring on-machine eliminates manual handling and the many issues associated with the transfer of components and set-ups between measurement devices.

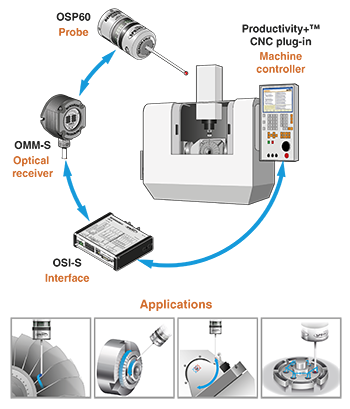

The analysis software for blade measurements is run directly from the CNC controller through the Productivity+™ CNC plug-in, so the measurement data is automatically available either through macro variables on the CNC, or on a connected PC for downstream data processing.

The system is capable of providing equivalent data when compared to existing on-machine probing systems, but with an increased level of speed and accuracy, derived from the 1,000 3D points per second measured by the OSP60 SPRINT probe. This means the time taken to integrate the system into an existing or new process is minimised.

Productive Process Pyramid™: Blade Toolkit

Explore the SPRINT system

SPRINT probe

The OSP60 scanning probe has an analogue sensor with 0.1 µm resolution in three dimensions, to provide exceptional accuracy giving the greatest understanding of workpiece form.

Constructed from the highest grade materials, the OSP60 is robust and reliable in the harshest machine tool environments withstanding shock, vibration, temperature extremes and liquid ingress.

A range of SPRINT specific styli are available to complement the enhanced capability provided by the OSP60.

Easily identifiable by their black stylus holder engraved with the exact ball diameter, these styli include a number of design elements to offer improved metrology performance for machine tool applications in comparison with standard styli offerings.

Marketing literature

Downloads

For SPRINT system related documentation please visit SPRINT system downloads.