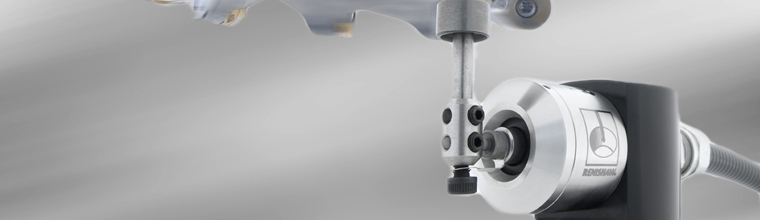

TS27R contact tool setting probe

TS27R

This text will be replaced

|

TS27R is mounted on the machine table. It enables the user to set tool length and diameter of rotating tools, and to carry out broken tool detection. As with all Renishaw hard-wired probe systems, TS27R requires the MI 8 interface or HSI to convert probe signals into an acceptable form for the CNC machine control. |

TS27R features and benefits

|

TS27R specification

| Specification | |

|---|---|

| Sense directions | ±X, ±Y, +Z |

| Weight | 650 g (23 oz) |

| Transmission type | Hard-wired |

| Uni-directional repeatability (max 2 sigma at stylus tip) | 1.0 µm (0.00004 in) |

| Trigger force Lowest force Highest force |

1.3 N (4.6 ozf) 2.4 N (8.5 ozf) |

| Stylus overtravel XY plane +Z direction |

±10° 5.5 mm (0.21 in) |

| Maximum recommended stylus length | Cranked stylus 27 x 33 mm (1.06 x 1.3 in) |

| Sealing | IP X8 |

| Mounting | 12 mm (0.5 in) T-bolt (not supplied). Optional spiral pins to allow accurate re-mounting. |

| Compatible interface | HSI or MI 8 /MI 8-4 |

Software for TS27R

Renishaw

tool setting software allows you to set tool length

and diameter offsets for single point and multiple point

tools, perform in cycle broken tool detection and manual

or automatic (programmed) positioning.